“Sushi Knife” and “Sashimi Knife” refers to "Wa-bocho" or the traditional Japanese style kitchen knives in a narrow sense. But now they sometimes represent whole Japanese kitchen knives worldwide outside Japan.

The Hocho is considered the most important tool for professional and amateur cooks, and a Japanese proverb says "The Hocho is the soul of the cook". Here, we're pleased to show you the comprehensive and detailed explanation about Japanese Sushi & Sashimi knives in this article.

1. General of Sushi and Sashimi Knives (Japanese Chef Knife)

Why so sharp?

In the high-end series for professional use, the Japanese-style kitchen knives are generally said still have better sharpness than the Western-style ones because of the better combination of production method, structure and materials, and are indispensable existence in the Japanese-style dish which requires delicate handling and razor-sharpness for especially slicing raw fish for Sashimi and Sushi in which a cutting end surface divides superiority or inferiority.

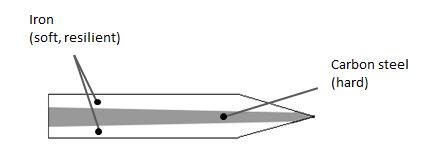

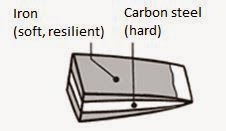

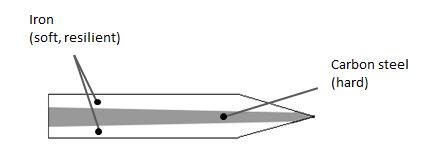

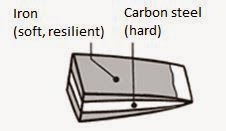

Originally, all Japanese kitchen knives - Hocho - clearly show their relation to the Samurai sword. The blades are forged traditionally in multiple layers, with an inner core of hard and brittle carbon steel, forgewelded with a thick layer of soft and more ductile iron steel sandwiched around the core so that the hard steel is exposed only at the cutting edge. Only this elaborate procedure ensures an optimum synthesis of breaking strength and ultimate sharpness.

The shape of these knives has developed solely from their intended purpose, which gives them an aesthetic quality not remotely influenced by fashion trends. The light wooden handles, the well-balanced design and the extraordinary sharpness make using Hocho a remarkable experience.

Nowadays stainless steel is often used for Japanese kitchen knives, and multi-layer laminated blade structure (so-called "Damascus") is used in more expensive blades to add corrosion resistance while maintaining strength and durability.

History

Japan has developed the aesthetics of food preparation like no other country, with the Hocho. Using the Hocho, the chef celebrates the art of cutting, which makes the preparation of fine fish and delicate vegetables a feast for the eyes. The razorsharp cut doesn’t crush the cells, the juice is retained, and the natural flavour of the foods comes into its own.

The oldest kitchen knives found in Japan are those made in the Nara period, around 8th century. They are now kept in “Shosoin”, the treasure house of the Todaiji temple in Nara. The knives look like primitive Japanese swords.

Much high-quality Japanese knives originates from Sakai in Osaka, Japan, the capital of samurai sword manufacturing since the 14th century. The Sakai knives industry started in the 16th century mainly for guns and swords during the Sengoku period (period of warring states in Japan). After the Sengoku period, Sakai had to change their industry to kitchen knives from such weapons. Through this process, the production method of swords was successfully applied to Japanese kitchen knives for excellent sharpness.

In 19 century, Japan opened its door to other countries to import many culture and technologies, called "Bunmei Kaika" in Meiji era, and Western-style knives in Japan were developed to meet the needs of Japanese chefs preparing non-Japanese cuisine for Westernization.

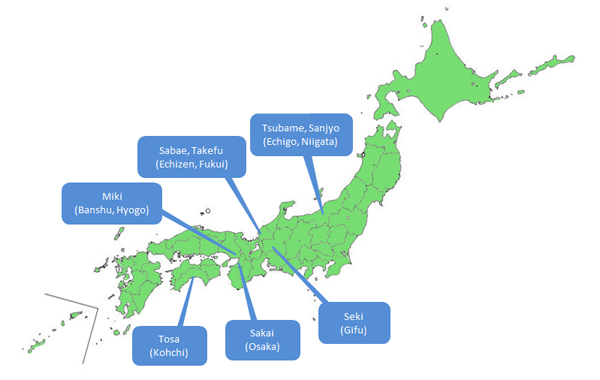

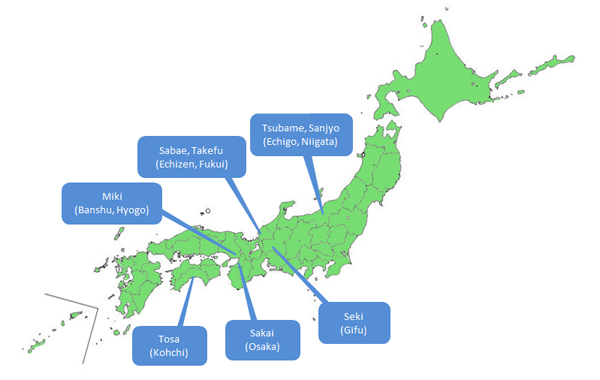

Production Area

The representative production areas of Traditional Japanese Kitchen Knives are Sakai (Osaka), Seki (Gifu), Tsubame/Sanjyo (Niigata), Sabae & Takefu (Echizen, Fukui), Miki (Banshu, Hyogo) and Tosa (Kochi). It is said that around 90% of the professional Japanese-style-food chefs in Japan use the knives made in Sakai.

Blade Styles

(1) Western versus Japanese Style Knives

Most knife manufacturers have both the Japanese-style knives and Western-style knives. There are lots of Japanese knives with Western-style handles or blades or both, pretty much any maker in Japan has several knives in Western-style and vice versa, most of all the major knife manufacturers in Europe and US make several Japanese influenced knives.

Japanese-style knives are usually made with harder steel, which means the blade holds it edge longer (it doesn’t need to be sharpened as often) and the edge itself can be cut a steeper angle. A Japanese knife is lighter, holds its edge longer, and its edge is cut differently than its counterpart.

It is recommended that you take your Japanese blades to a professional sharpener. Japanese-style knives are more about precision and exactness.

Western-style knives originally used a softer steel though they are now much influenced by Japanese-style. Keep in mind softer steel does not always mean inferior steel. Due to the softer steel the blades do not hold their edge as long as their Japanese counterparts, but are much easier to sharpen and are not as brittle. When held western-style knives have a bit more heft which can be a good thing, depending on your preferences.

(2) Western Style Knives (generally double-edged)

In Japan, Western-style knives were developed to meet the needs of Japanese chefs preparing non-Japanese cuisine. Today, Japanese knife makers are engineering new advanced manufacturing processes such as ‘sub-zero tempering’ and premium trademark-formulated knife steels to produce exceptional Western-style knives.

However, what really sets Western-style knives from Japan apart from the typical Western-style knives is it's strong thin blade.

(3) Japanese Traditional Style Knives (generally single-edged)

Originally, all Japanese kitchen knives were made from the same carbon steel as katana.

More expensive multi-layer (more than three-layer) knives have a similar quality, containing an inner core of hard and brittle carbon steel, with a thick layer of soft and more ductile steel sandwiched around the core so that the hard steel is exposed only at the cutting edge.

Nowadays stainless steel is often used for Japanese kitchen knives, and multi-layer laminated blade structure is used in more expensive blades to add corrosion resistance while maintaining strength and durability.

Recommended product line can be checked here.

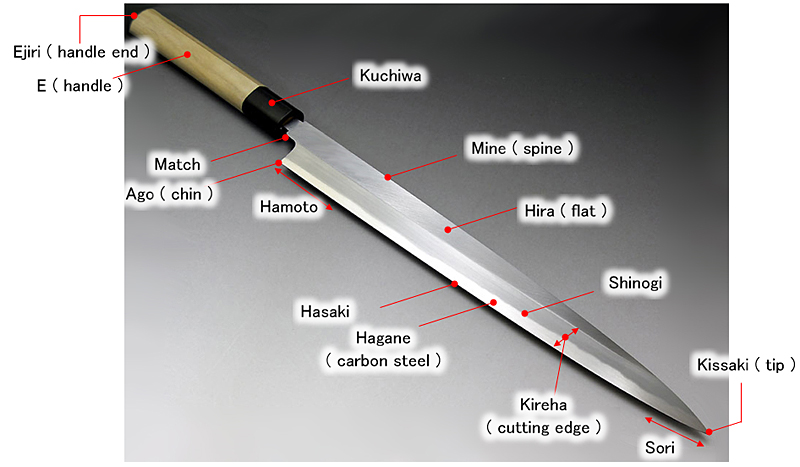

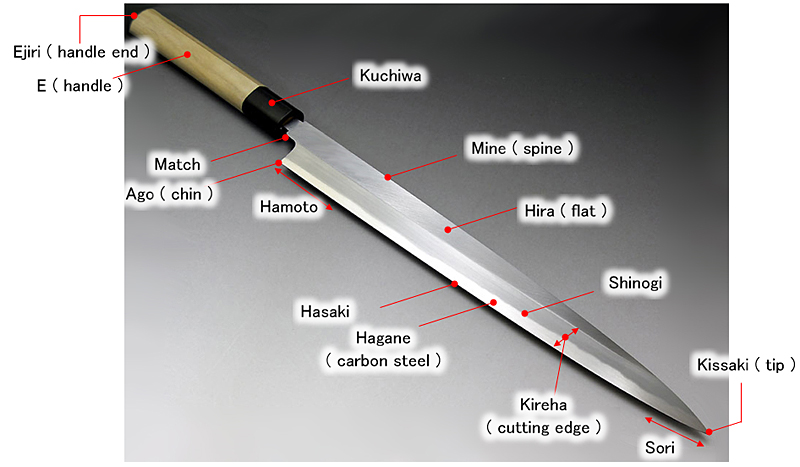

2. Parts of Japanese Sushi Knife

Sushi and Sashimi knives are extremely sharp and made for a specific task so that they require very specific instructions. First of all the name of parts should be known for better handling and maintenance.

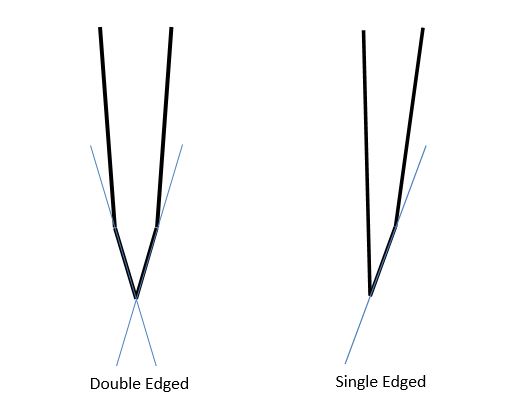

Double-edged v.s. Single-edged Kitchen Knives

Double edged — sharpened on both left and right side of the blade

*sharpening balance ….. mostly 50:50~70:30 (sometimes 80:20~90:10)

*mostly for left-and-right handed if the balance is within 50:50~70:30

Single edged — sharpened on just one side of the blade surface

*for left or right handed

*sharpening balance ….. 100:0

Japanese style blades are often single-edged, and Western style blades are double edged except in some cases. The information about the edge type is shown in almost all the item pages in the Hocho-Knife store.

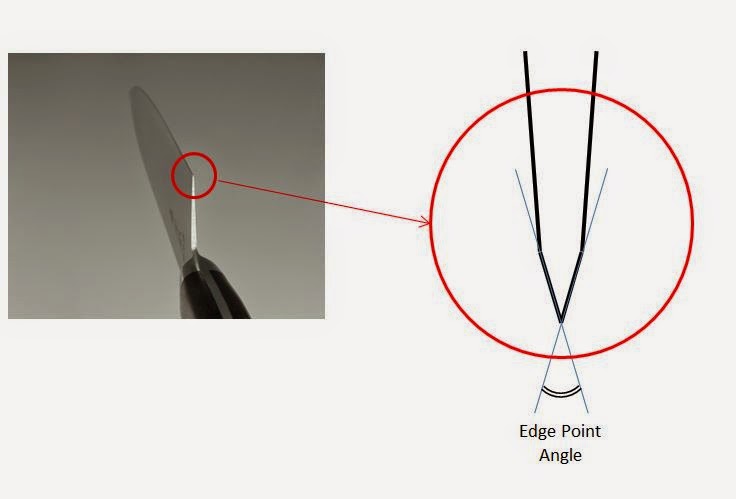

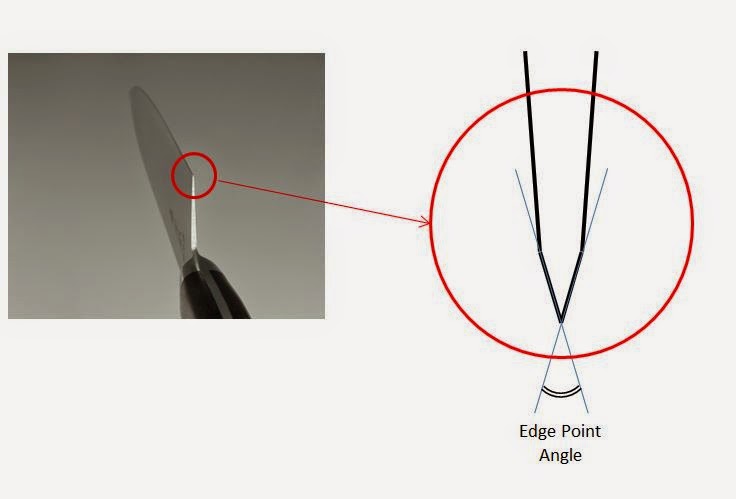

Edge Angle

In general, it may often be understood that more acute angle provides a better sharpness. Do you think it is really true??

There is thought a misunderstanding. Angle of the cutting edge (at the edge point) does not affect the ability to cut things.

Why?

To think about cutting a thin material, both an obtuse and sharp kitchen knife do not make a significant difference in the sharpness because there is almost no distance that the knife go interrupts.

That’s why the edge point of professional sashimi knives is often sharpened at about 35~45 degrees(!) , but the sharpness is excellent with less-likely chipping.

(General household all-purpose kitchen knives have sometimes been sharpened at about 25~30 degrees.)

For less resistance when the knife goes interrupt the cuttings, you may only feel that sharpness is good if you use an very acute-angle blade.

It is the fact that smaller angle provides better sharpness feeling because of less frictional resistance.

However, the smaller angle at the cutting edge would cause easily chipping when you try too hard to cut a hard thing (such as pumpkin and frozen foods).

FYI, for double-edged Western style kitchen knives, about 25~35 degrees is often relatively said good from a view of the balance between sharpness and less-likely chipping.

Please refer to the article of "what angle I should sharpen the knife at?"

3. Types of Kitchen Knives

The following table is the list of all the sushi and sashimi knives. We'd appreciate it if you could read and understand the explanation to select the best knife for your purpose.

| Western Style Knives |

|

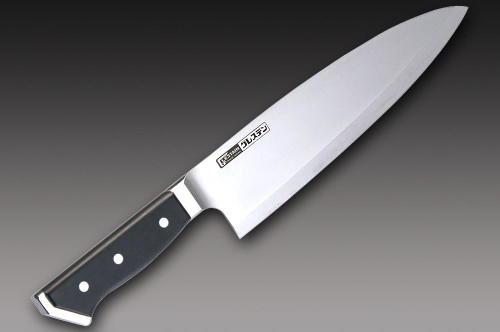

Gyuto

(Chefs knife)

|

Versatile cooking knife for cutting up, filleting and preparing meat and fish. Slim blades for intricate tasks, pull or push cuts. Most standard and popular blade among Western Style knives, so called “Chefs Knife”. Gyuto is one of the most versatile blade type, suitable design for cutting, slicing meats, vegetables and fishes. |

|

Santoku (All-Purpose knife)

|

All-round knife for meat, fish and vegetables (Santoku = the three virtues). Wider and rounded shape is suitable design for especially vegetables, but also cutting, slicing well for the fishes, meats. Santoku knife is popular knife and can be recommended as Multi Purpose Home Chef knife. The Santoku is sometimes called "Bunka" Bocho. |

|

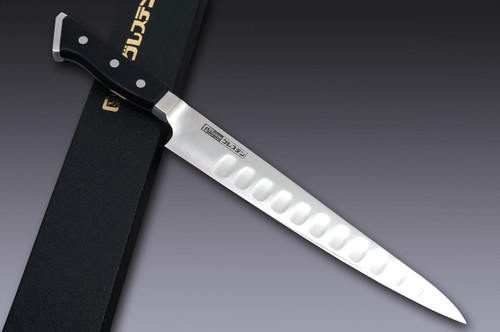

Sujihiki/ Slicer/ Carving knife

|

"Sujihiki" or Slicer (or Carving knife, depending on the purpose and detailed shape) has narrower and longer blade. The Sujihiki is suitable design for the slicing tasks. If you often cut and slice (fillet) fishes, meats, hams etc, Sujihiki is the best choice for your needs. |

|

Salmon (Salmon and Meat Slicer)

|

For slicing smoked salmon, meat and ham. This type of knife has a lot of dimples on the side of the blade to prevent piece of salmon from being adhered. |

|

Wave knife (Bread Slicer)

|

The Bread Slicer is often called "Wave knife" that has of course a lot of wave patterns at the edge of the blade. It is suitable for cutting bread, cakes, and sponge cakes. |

|

Boning knife

|

The typical type of western boning knife that has a sharp point and narrow blade, that iis used in food preparation for removing the bones of poultry, meat, and fish. |

|

Honesuki (Sabaki)

|

Honesuki or Sabaki has a suitable design for de-boning process, cutting a Chicken, filleting a fish. Versatile knife for special purpose. There are two type of Honesuki--- Kaku (square) and Maru (Saki-maru or round). |

|

Garasuki

|

Thicker and longer than Honesuki. Generally used for butchering poultry. |

|

Petty (Utility knife)

|

Small all-purpose knife for fruit, peeling and cutting small objects. Compact, good handling of Petty knife is suitable design for peeling fruits, preparing various kinds of foods and precise works. |

|

Paring / Peeling knife

|

Small and compact size. The Paring knife is suitable design for peeling, cutting fruits and vegetables. Tiny and cute looks, yet very useful knife. |

|

Frozen Food knife (Reito)

|

Designed to cut frozen food. Sometimes called "Reito" in Japanese. Common type of the Frozen Food knife has a sturdy blade with a coarse, saw-toothed edge. Another type of the Frozen is like a sturdy, thick and large chef knife with no saw-toothed edge for semi-frozen food. |

|

Cleaver

|

Large knife, that varies in its shape but usually resembles a rectangular-bladed hatchet. Largely used as a kitchen or butcher knife intended for hacking through bone. The knife's broad side can also be used for crushing in food preparation. |

|

Chinese Cooking knife

|

The Chinese Cooking knife is the rectangular-bladed, all-purpose knife traditionally used in China, and many other Asian countries to prepare a variety of meats, fish, and vegetables. After the world war II, made-in-Japan knife began to surface in Japan and recently in Asian countries. |

|

Western Deba (Yo-Deba)

|

Western Deba or Yo-Deba is the Western-style version of the traditional Japanese deba. The edge is generally double-edged. The Western Deba has heavier weight and more durable edge, designed for harder use --- for cutting a fish, chicken and shrimps, lobsters. |

| Japanese Traditional Style Knives |

|

Deba

|

The "Deba" is designed for cutting fish and light mincing. The back of the blade can be used to chop thin bones. Thick and Heavier blade of Deba has good durable edge, suitable for cutting a Fish, a Chicken, also for filleting tasks. Its history goes back to the Edo era in Sakai, Japan. |

|

Ai-Deba / Mioroshi-Deba

|

The "Ai-Deba" is slightly narrower and thinner than a traditional deba, a heavy knife that was made to filet and butcher whole fish. "Mioroshi"Deba is more narrower than Ai-Deba. (Width : Deba > Ai-Deba > Mioroshi-Deba > Yahagiba) |

|

Funayuki Deba

|

A filet knife, a multi-purpose Japanese traditional one. The name "Funayuki" or "Going on a boat" in Japanese. The profile is similar to a Deba, but is thicker than Deba to meet multi-purpose on a boat. This lightweight knife is easy to use on smaller fish.

|

|

Yanagiba (Sashimi)

|

A Sashimi Knife, for cutting and filleting fish or ham with a pull stroke. Slim blade in the shape of a willow leaf or Katana (sword). Long and Narrower blade is suitable for slicing tasks. Especially for preparing fresh, good&beautiful shape of raw fishes (sashimi). The Yanagiba is called "Shobu" and popular in Western Japan (around Osaka and Kyoto). |

|

Takohiki (Sashimi)

|

Square shape, longer blade of Sashimi Knife, designed for same purpose as Yanagiba. Not for slicing "Tako" (Octopus) but for making Sashimi. The edge line is almost straight, while Yanagiba knife's blade edge line is more curved towards the blade tip. The Takohiki was popular in Eastern Japan (around Tokyo). |

|

Fuguhiki (Sashimi)

|

A Sashimi knife for a specific purpose, originally designed for cutting, slicing Tessa (Blowfish Sashimi). Its blade shape is similar to Yanagiba, but has narrower blade width and thinner blade. It is suitable design for thinner cutting, slicing tasks. |

|

Sushi-Kiri

|

"Sushi Kiri" means slicing Sushi in Japanese. It is for slicing roll sushi and Hako Sushi (Battera Sushi). It is popular in Western Japan (around Osaka and Kyoto). Around Tokyo area, Yanagiba or Takohiki are used for cutting roll sushi. |

|

Usuba (Vegetable knife)

|

The Usuba has a thin & straight blade for clean cutting on the chopping board; paper-thin slices are no problem, even with ripe tomatoes. Wide blade for good guidance along the finger knuckles. It has been used by professional chefs in Eastern Japan (around Tokyo). |

|

Kamagata-Usuba

(Vegetable knife)

|

It is another type of Usuba with a round back as well as with a thin & straight blade. That has been used by professional chefs in Kansai, Japan (around Osaka and Kyoto). The small types are used for chamfering vegetables. |

|

Nakiri (Vegetable knife)

|

The Nakiri has a very thin & straight blade. Long time ago before Santoku grew popular, the Nakiri was generally used as a common kitchen knife mainly for home use. |

|

Unagi-Saki

|

The Unagi-Saki is a knife for cutting eel. There are generally three or four different types in shape --- Kanto, Osaka, Kyoto and Nagoya types of blades. |

|

Tuna-Kiri

|

Tuna Kiri or Maguro Bocho in Japanese is an extremely long & specialized Japanese knife to cut and fillet giant tuna. Its blade is usually 50cm to 90cm long. The shape is similar to takohiki. |

|

Ohter Types

|

(containing Western & Japanese Style different knives)

Tomato knife, Steak knife, Proty knife, Sole knife, Hamo-Kiri, Kai-Saki, etc. |

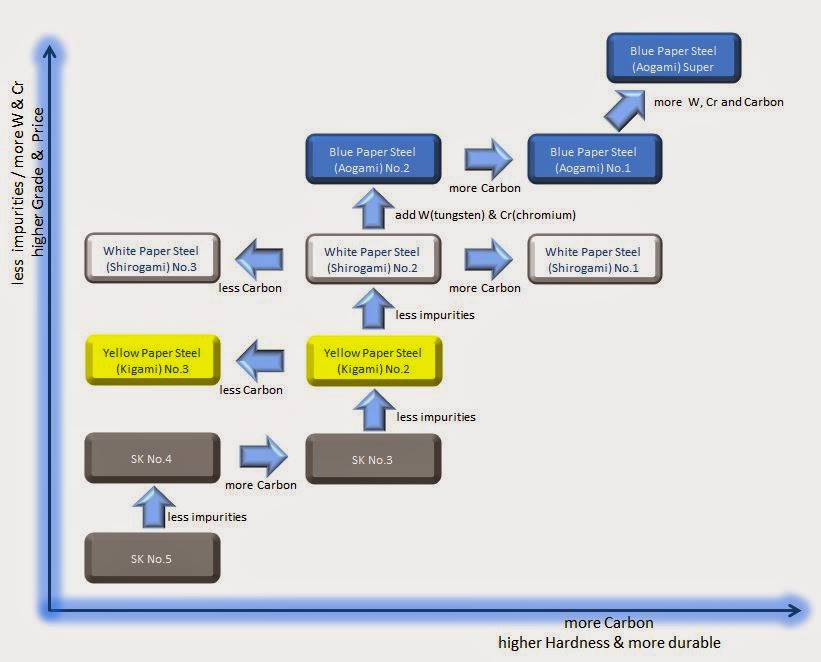

4. Steel Qualities of Kitchen Knives

Carbon Steel

Carbon Steel — often used for Traditional Japanese Knives, good Quality, not Rustproof. The Japanese company Hitachi Metals makes special cutting steels which represent the highest global standard and are used for almost all the Hocho we offer. These Yasuki Special Steels (YSS), named after their place of origin, are produced from iron sand, the same material that was used to make the legendary Samurai swords. They have a highly pure structure and thus offer the best achievable sharpness for cutting.

We’re pleased to introduce the Steel Qualities for Traditional Japanese Knives as follows.

Blue Paper Steel(Aogami)

Hitachi high carbon steel, specifically developed for tools and knives. This one has highest wear resistance and lowest toughness. Very good steel, and very popular choice for high end Japanese kitchen knives. A lot of Japanese custom makers use it. Easy to sharpen, even high hardness. Edge holding is just outstanding. Original Japanese knives made from these materials are treated with non-corrosive, food-safe oils (e.g. camellia oil) to prevent oxidation.

White Paper Steel(Shirogami)

Identical to Blue Paper Steel(Aogami) , except for the absence of Cr and W. It’s very pure carbon steel. Very popular knife steel for high end Japanese cutlery and especially with Honyaki type blades.

Very good edge holding, very high working hardness. This means you can grind it to exceptional sharpness, which it retains for a long time. These blades are particularly suitable for the gentle preparation of foods – but they are prone to oxidation, which means rust.

Yellow Paper Steel(Kigami)

Better steel compared to SK series, but worse than both, Aogami and Shirogami. Used in high end tools and low/mid class kitchen knives.

SK Steel series

Solid performer as a cutlery steel. Low grade steel, mainly due to impurities. Used mainly in hand tools like axes, hammers and cheap kitchen knives.

Japanese Steel(Nihonko, Hagane, Virgin Carbon Steel)

Important steel that has been used to produce knives in Japan since ancient times, providing better sharpness than common stainless steel. The Japanese steel is a premium grade of steel that boasts extremely high carbon content. It is manufactured in limited quantities in Japan. The steel is harder than German steel and has a greater sharpening potential. It also maintains an edge longer than other lower-carbon steel formulae. These features make Japanese steel the ideal material for manufacturing high performance cutlery.

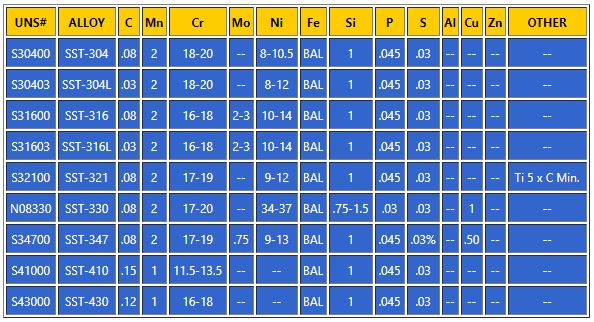

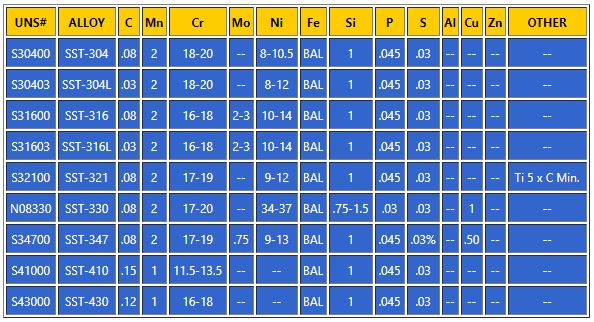

Stainless Steel

Stainless steel is an alloy of iron, approximately 10~15% chromium, possibly nickel, and molybdenum, with only a small amount of carbon. Good Stainless steel blade kitchen knives make good rust resistance, easy maintenance, good sharpness, edge retention and ease of re-sharpening. Therefore, they have become more and more popular among beginning users to professional users in this generation.

The chart such as the chart below seems popular, and you may get numeric material information.

This time, we do not explain about the materials in the chart, but the frequently-heard expression dedicated for kitchen knives as follows,

High Carbon Stainless Steel

The high carbon stainless steel is a metal alloy containing relatively high amounts of carbon. The amount of carbon can be as much as 1.2% and as low as 0.2%. The reasons for this vary with the manufacturer and the type of blade they’re creating. It is intended to combine the best attributes of carbon steel and ordinary stainless steel. The high carbon stainless steel blades do not discolour or stain, and maintain a sharp edge for a reasonable time.

SG-2 (Super Gold No.2)

This is more common and popular Powdered High Speed Tool Steel for knife blades. You can taste speechless cutting performance, great edge retention and easy maintenance (resistance for the rust). Made by Takefu steel company. Achieves very high hardness. Some high-class knives are made of this SG-2, Elite line of Shun and Yaxell GOU series.

VG-10

One of most popular and high ranked Japanese Stainless Steel for sharpness, edge retention and durability. Cobalt added Special high Carbon Stainless Steel, often be called as “Cobalt Steel”. Many of makers use VG-10 for the Damascus blade too.

VG-1

This is good basic and common Japanese Stainless steel which makes high hardness, edge retention, strength and rust resistance. Both VG-1 and VG-10 are produced from Takefu Steel Company.

ZDP 189

Extremely high carbon and chromium content --- Carbon: 3%, Chromium: 20.0%, Tungsten: 1.50%, Vanadium: .10%, Molybdenum: 1.30%. Very high hardness, several makers harden it to 65 or even 67HRC This is one of the most recent developments in PM steels. This is one of the harder steels to sharpen by hand. It is also known as MC66 and is used by Henckels under that alias.

Gingami No.3(Gin-san)

Fine Japanese Steel Company Hitachi’s special stainless steel which makes similar sharpness, edge retention as Carbon Steel. Gingami No.3 often be used for Japanese Traditional Style knives

Sweden Stainless Steel

The Pure Stainless Steel material from Sweden. We heard several makers use Sweden Stainless Steels for the stable quality control. Selected Sweden Stainless steel material are easier for making process, heat-treating process, and it will help for making stable good quality control.

Molybdenum Vanadium Stainless Steel

One of common and good standard, stainless steel for the knife blades. We often recommend Molybdenum Steel Kitchen knives for first users and beginning users of Japanese knives because of its characteristics. Ease of re-sharpening, good durability and rust resistance, and reasonable price range.

5. Blade Structure

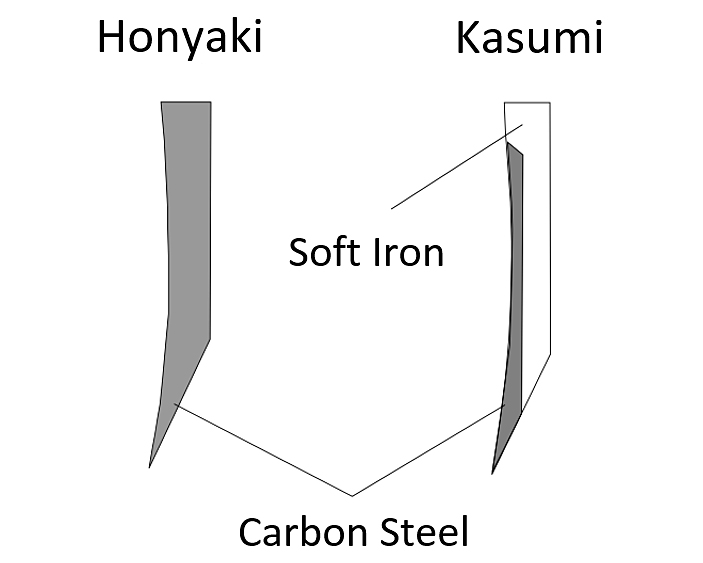

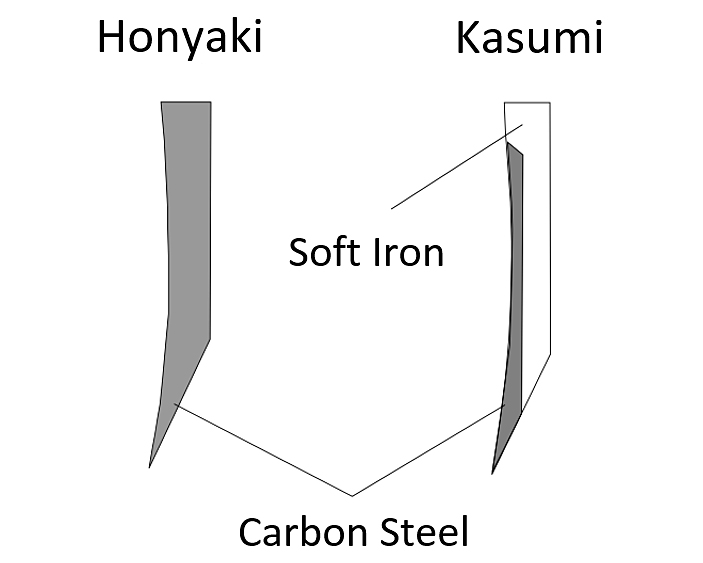

Honyaki and Kasumi

One of our customers gave us a question, ” I am looking for non stainless, that is a full carbon knife. Is the honkasumi gyuto made of a mono steel or clad knife and what is the hardness of the steel?”

That is a good question, because there are two basic categories of traditional Japanese knives, Honyaki “true-forge” and Kasumi “mist”. These categories are defined by the forging method and material used in forging.

Honyaki Knives

Honyaki knives are forged solely from one material: high-carbon steel (called “Hagane”). Generally the Hagane is White steel(Shirogami) or Blue steel(Aogami). The structure method used to make Honyaki knives is similar to that used to make traditional Japanese swords, which is a very difficult and long process.

After being heated treated, the steel is hammered repeatedly to form the shape of a blade and evenly distribute the carbon and chromium molecules. It requires the precise techniques of skilled and experienced craftsmen.

The blade of a Honyaki knife is hard, so it retains its sharpness for a long time; however, they are prone to chipping and difficult to sharpen. Since they cannot be mass-produced.

Honyaki knives are expensive, compared to other types of knives. They are primarily for professional chefs and are the highest quality traditional Japanese knives.

The following is one of the Honyaki knives,

“Sabun Honyaki (Gyokuhaku-ko) [with Saya]”

https://www.hocho-knife.com/sakai-takayuki-honyaki-water-quench-aogami-2-steel/

https://www.hocho-knife.com/goh-umanosuke-yoshihiro-honyaki-shirogami-2-awhy-e/

http://www.hocho-knife.com/sabun-honyaki-tamashiro-steel-with-saya/

Kasumi Knives

Kasumi knives are made from two materials by joining a piece of soft iron (Jigane) with a piece of high-carbon steel. “Kasumi” means “mist” which refers to the hazy appearance of the soft iron body of the blade, as contrasted to the glossy appearance of the carbon steel.

The actual cutting edge and backside of the blade is carbon steel, while the supporting spine and rest of the blade is soft iron, which makes the sharpening process easier. Kasumi knives are less expensive than Honyaki knives and are easier to use and sharpen.

In addition, Kasumi category has a higher grade, “Hon-kasumi” or “Hongasumi”. The hongasumi knives are made in the same way as Kasumi knives. But the quality of steel used is often higher, and more processes and work are required for its structure than Kasumi knives.

“Masamoto Honkasumi Gyokuhaku-ko”

http://www.hocho-knife.com/masamoto-honkasumi-tamashiro-steel/

“Sakai Takayuki Kasumi”

http://www.hocho-knife.com/sakai-takayuki-kasumi/

Outline of Multi-Layer Structure

Originally, many Japanese kitchen knives clearly show their relation to the Samurai sword. The blades are forged traditionally in multiple layers, with an inner core of hard and brittle carbon steel, forgewelded with a thick layer of soft and more ductile iron steel sandwiched around the core so that the hard steel is exposed only at the cutting edge.

Only this elaborate procedure ensures an optimum synthesis of breaking strength and ultimate sharpness.

The shape of these knives has developed solely from their intended purpose, which gives them an aesthetic quality not remotely influenced by fashion trends. The light wooden handles, the well-balanced design and the extraordinary sharpness make using Hocho a remarkable experience.

Nowadays stainless steel is often used for Japanese kitchen knives, and multi-layer laminated blade structure (so-called “Damascus”) is used in more expensive blades to add corrosion resistance while maintaining strength and durability.

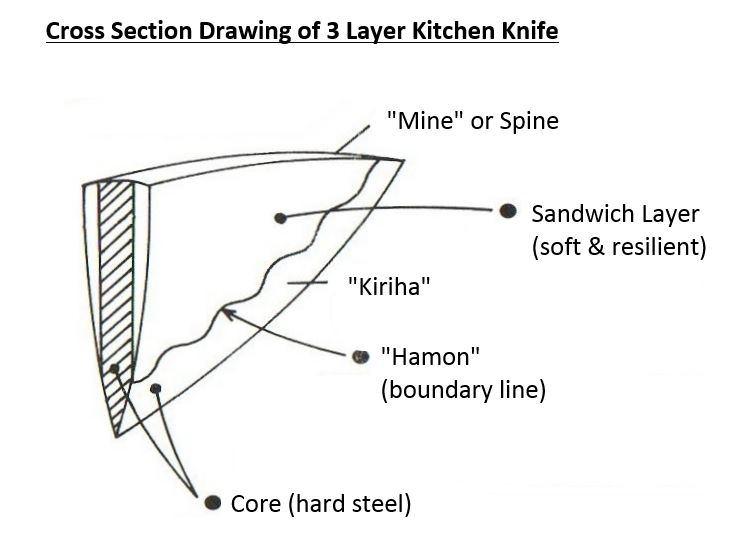

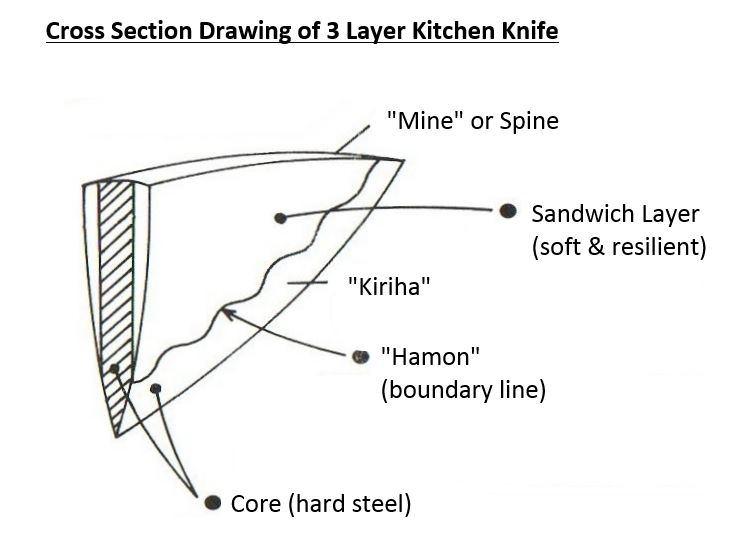

Hamon

A customer asked about the wave line on a popular kitchen knife, “Hi there, I’ve got the knife. awesome sharpness, love it. Just one thing bothers me – there are two scratches on both sides each of the blade along all way along the cutting edge. I am not sure what is it. Is it a defect?”

As you know, the lines are not a kind of defect but necessary lines on 3 Layer Kitchen knife. The wave lines are called “hamon”, boundary lines between the core and sandwich layers on both side of the knife.

The hamon is beautiful and unique one by one knife, made by harmony of two different materials.

Generally, many of middle and high class Japanese kitchen knives clearly show their relation to the Samurai sword. The blades are forged traditionally in multiple layers, with an inner core of hard but brittle steel, forgewelded with a thick layer of soft and more ductile steel sandwiched around the core so that the hard steel is exposed just at the cutting edge. Only this elaborate procedure ensures an optimum synthesis of breaking strength and ultimate sharpness.

Damascus Pattern

Some like Damascus knives because of the aesthetic value for their gift, collection and cooking before people. If you personally like the Damascus pattern very much, we recommend one of the beautiful Damascus knives.

From a view of strength and durability, such a multi-layer structure as Damascus can not simply be said “no meaning”.

Before discussion of Damascus, we have to start from the benefit of multi-layer blades. The benefit of the sandwiching structure is to strike a balance both the harder & sharper edge and better durability of the entire blade.

The most simple multi-layer blades have a three layer structure, made of a hard steel core that is sandwiched by soft (resilient) steel so that the hard core is exposed only at the cutting edge. That realizes better durability or chip-resistance.

* Hard steel core is generally easier to be chipped, that’s why the sandwich structure can be a good solution.

** If the core is not stainless (like high carbon steel) covered by stainless steel layers on both side, the blade totally get good rust-resistance as well as chip-resistance.

One of the applied approach of the multi-layer blades eventually leads to a Damascus pattern. Therefore, such a multi-layer structure can not simply be said “no meaning“ from a view of strength and durability.

***Be careful that there exist blades which have damascus pattern to the end of the cutting edge. Such a knife has just aesthetic value without the above benefit of the sandwich structure.

Many sandwich outer layers covering the center core realize the unique Damascus pattern for each knife. You can get only one design of the blade in the world. Therefore Damascus knives are much recommended as a gift as well as just for better cooking experience. One demerit of the Damascus knives is the cost because of additional production process.

Needless to say, it’s important to know what materials are used as the core and sandwich layers first.

FYI, the core is sometimes not a simple high carbon steel but VG-10 or SG-2 and so on. We think they are excellent materials for a sharp knife.

6. How to use Sushi and Sashimi Knives

How to slice Sashimi

This video kingly advises us with slow motion how to cut sashimi in the right manner, and we believe you can understand the essential technique very well.

How to cut Vegetables

How to cut vegetables is very basic but important for all the chefs. You can review the technique in the following video, where Japanese professional chef tells the better way.

Application

Using a razor sharp Japanese kitchen knife “Hocho”, a chef showed an amazing Super Cutting demonstration.

Such a skill is said not so special but a basic technique acquired from a training to be a true Japanese cuisine chef.

Do you think that it is true?

7. Knife Sharpening and Maintenance

Whether is the knife ready to use straight away?

Recently, a customer asked us, “whether is the knife ready to use straight away or needed to be sharpened by myself?” Normally, a obtuse angle finishing at the blade edge by a machine in manufacturers (called “standard blade finishing (sharpening)”) is applied to most of the knives that are stocked and displayed in the store.

It is thought enough for general use, because manufacturers apply the standard finishing for various possible application. (Regarding some high-end knives, the edge of the blade has to be hand-finished one by one before shipment. That is stated in the description in the item page.)

(machine finishing)

(hand finishing)

Professional chefs often apply a hand-finishing (fine-grinding by hand) to the blades by themselves just after they buy the knives. If the chefs would like to cut just soft ingredients, acute (sharper) angle at the edge would be great to stimulate its cutting performance.

On the other hand, if they have to cut hard ingredients, obtuse angle at the edge must be good to prevent the edge from easy chips.

Some professionals make their knives easier to use through such a self-finishing customization as semi-single edged, semi-double edged (like 70:30) or as special edged with different edge angles from the point to point.

How to Sharpen Double-edged Knives

In most cases, kitchen knives can successfully be re-sharpened. Do you like to try that for razor-sharpness ? We recommend to sharpen your knife with waterstones for better sharpening, not with a grinding rod.

Does that look to really expend much time and effort compared to the benefit?

Don’t worry about it. It get easy to for you use the stone soon.

Double-Edged Knives are generally called "Ryo-ba" in Japanese. "Ryo" is the both side, and "ba" is the edge of blade. Western style knives are mostly "ryo-ba" for right and left-handed persons.

In Japan, a lot of types of Western style knives are manufactured from Meiji-era, 19th century. The representative Japanese ryo-ba blade is made of hagane in the core sandwiched by soft steel layers from the both side.

Its quality is now said the best, and have got more and more popular riding a wave of Japanese food spreading in the world.

The following video tell you how to sharpen a knife in English, that will successfully help you.

Of course, please be noted that it is sometimes impossible if the issued knife has a large chip and damage or if the blade was seriously bent.

How to Sharpen Single-edged Knives

“Single-Edged” blade is the basic form in the traditional Japanese kitchen knives for a long time, that is completely different from that of the traditional Western knives. But, some don’t know how to rightly sharpen a “Single-Edged” knife where the edge has unfortunately gotten chipped, bent and rusted. If you learn how to sharpen, your knives are sure to get extremely sharp again.

Let’s watch the following video that teaches you plainly the right method of “Single-Edged” knife sharpening.

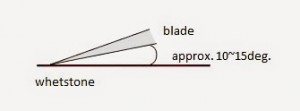

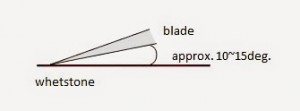

What angle I should sharpen the knife at?

Some customers have asked so far, “Just wondering what angle I should sharpen the knives I bought at?”

The sharpening angle depends on the intended use,of course. Generally speaking, approx. 10 degrees between the surface of the blade and whetstone would be recommended if you cut only soft things.

12~15 degrees would be recommended if you cut some hard materials.

**This is just for double-edged blades.

Please refer to the attached picture.

The following Sharpening guide will help you effectively and easily. Please try it.

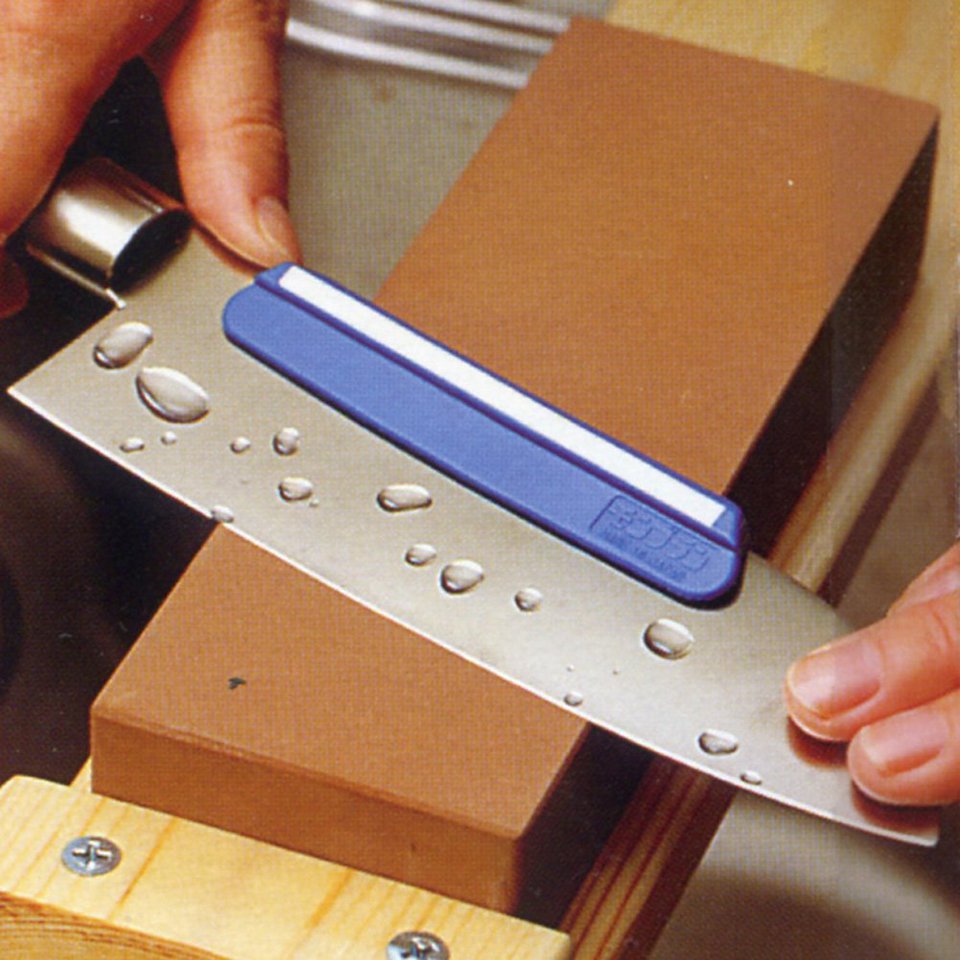

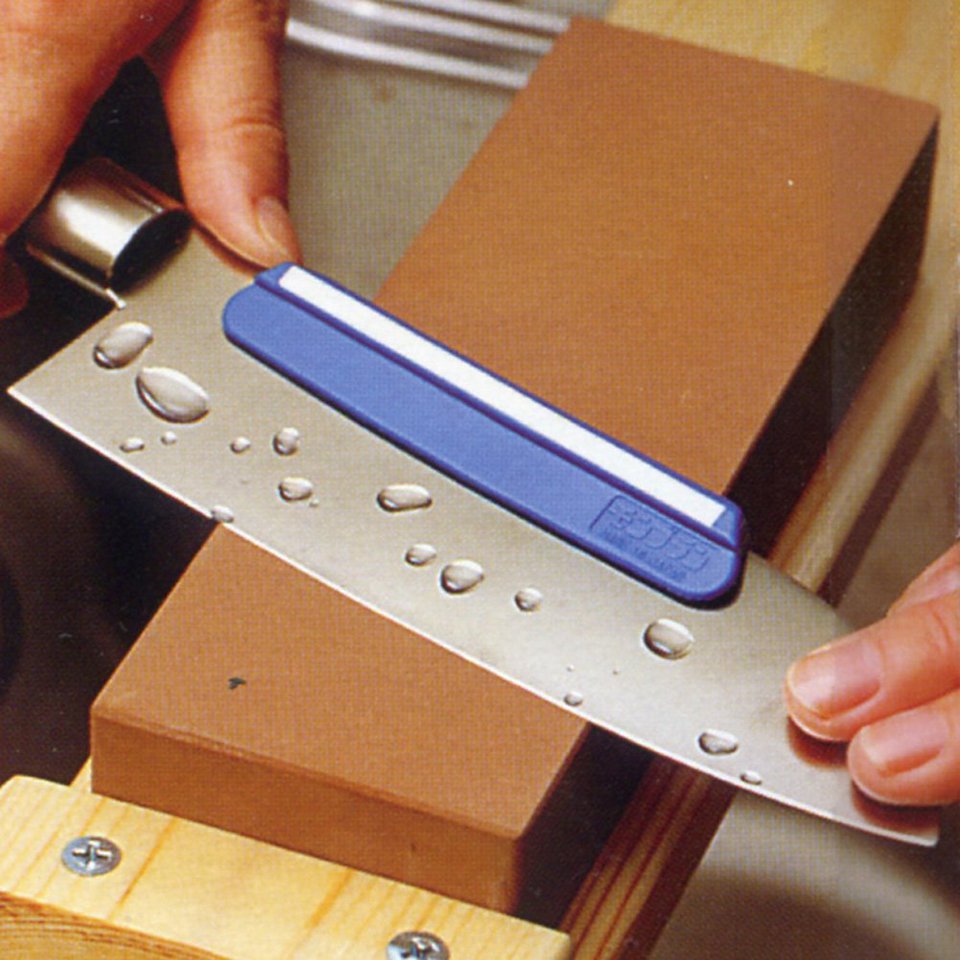

Sharpening Guide Tool

For better sharpening you knives, we recommend you to use a Sharpening Guide. The guide is designed to help maintain the correct angle for sharpening knives when sharpening with a whetstone.

Any time you remove the guide rail from your knife, rinse and clean it thoroughly to remove any residue from the stone that may remain inside the guide rail.

The guide slides onto the spine of the knife to keep your angle constant when sharpening on a stone as shown in the following video (example),

To further insure that no residue remains, it is recommended that you pull a clean towel through the guide rail after rinsing.

If you fail to remove the entire residue from the guide rail, the residue may scratch the knife the next time the guide rail is used.

Works great and has a white slip strip to make for easy use and prevents you from scratching or gouging your stones.

We recommend you put some painter’s tape on your knife to avoid minor scratches when slipping the sharpening guide on and off your knife.

How to get rid of rust on the blade

Recently, a customer asked us for the better way of maintenance of Japanese traditional-type kitchen knife, “I used the sushi knife last night to slice vegetables for dinner. After using, I washed the knife, dried with a paper towel, and let it air dry until this morning.

However, I noticed a discoloration on the blade this morning. Is there anything I can do to keep it from changing color? Did I wash the knife improperly? Is there something I can apply to the blade after washing? Any help would be greatly appreciated.”

The question is not special and many might want to know how to do it.

The blade of Japanese traditional-type kitchen knives is almost made of an iron or carbon steel, not stainless one. It has very good edge holding, very high working hardness. But the material is prone to oxidation or rust. You should care for the knife every time of use — to keep the blade dry and clean.

The carbon steel is easy to oxidation or rust especially when the blade is very new. If it has gotten rusted, please try the following,

(1) wet the knife with water, put the cutting board.

(2) sprinkle evenly powder cleanser so as to cover the rust.

(3) put a cork in the water.

(4) polish the rusted area with a cork, keeping the knife from moving.

How to prevent rust during stock

It is likely to get rust on the blade made of steel if you do not care for it. Especially most of Japanese traditional style knives are made of carbon steel, that is very sharp but easy to get rust. To prevent rust, you need to do some adequate maintenance.

Don't mind! It is very simple.

(1) scrape or wash the knife cleanly with cleanser, and let it dry well by a dried towel.

Please don't roast the blade over the fire. It causes degrade its sharpness badly.

If you need to sterilize your knife, we recommend hot water sterilization.

(2) put a thin layer of plant-derived oil on the blade.

(3) Finally, warp the blade in a newspaper for storing the knife.

Why newspaper?

Because ink on the newspaper contains some oil to prevent from rust.

Maintenance after every use

Anyway, the daily small maintenance is the most important for your lovely knives.

(1) wash the knife clean after every use. (use the cleanser as explained in the above if you have time)

(2) wipe the surface of the knife with dry tissue paper, after pouring the boiling water over the blade

(3) wipe off its surface with a little bit cooking oil by tissue paper

Hoping that your knives will keep their sharpness for a longer tim<